How Does an Oxygen Deficiency Monitor Work?

With the name of oxygen monitor, you might wonder why these devices are used in the presence of other gases, such as nitrogen. Gases like nitrogen and argon deplete oxygen from the environment. If you introduce nitrogen into a lab setting, for example, oxygen levels start to drop. Since nitrogen does not have a color or scent, lab workers would be unable to perceive the leak.

As oxygen levels fall, lab workers would become confused and experience respiratory difficulties and loss of coordination. In a matter of minutes, lab workers could die from asphyxiation.

When an oxygen deficiency monitor is installed, it becomes easy to tell when a potentially hazardous gas has escaped into the room and is depleting levels of oxygen. Set to go off when oxygen falls below safe breathing levels, the O2 monitor flashes an alert and sounds an alarm to provide immediate notification. This way, staff have enough time to safely clear the premises before experiencing negative health effects. These monitors offer a cost-effective way to protect staff and maintain a safe working environment, and are a best practice for working environments that use these gases.

Where Oxygen Monitors Are Installed

Since oxygen monitors protect against a range of gases, they are used in many different industries and working environments. Some of the places that use oxygen monitors include:

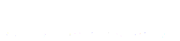

- Laboratory settings – As the example above indicates, lab workers often directly work with potentially dangerous gases in study, research, and teaching. An oxygen monitor in the lab setting operates as discussed in the example above, alerting workers if gases leak. Laboratories are required to install these devices by the 2008 NIH Design Requirements Manual as well as existing OSHA regulations.

- Colleges and universities – Since universities have laboratories and work with these gases in teaching and research environments, it should come as no surprise that they have oxygen monitors. In the university setting, these monitors may be installed in classrooms, labs, research facilities, and storage areas to protect students, staff, and facilities workers. As this example illustrates, it is important to use a separate oxygen deficiency monitor in any area where these gases are used or stored. From a leaky pipe to a faulty storage tank, gas could escape in many ways – always posing a health risk.

- Medical settings – Hospitals and medical centers need to keep blood, tissue samples, and other supplies properly chilled so they can be used for patients. The cryogenic gases are an easy, inexpensive solution to the storage issue. Yet, anywhere these gases are being used, there is the risk for a leak. In medical settings, an O2 monitor may be used in hallways and individual rooms where nitrogen containers are held.

- Food processing plants – It is common to use nitrogen gas in food processing plants as a safeguard against oxidation of food and beverage products. When oxygen enters the food packaging, it causes early ripening and spoilage. Thus, nitrogen gas helps to protect the food and allows for longer storage on the shelf. Since the gas is cheap, environmentally friendly, and easy to use, it is a common solution in the food processing industry. To protect food processing workers, it is critical to have an oxygen monitor evaluating levels of oxygen in the air in case of a nitrogen leak.

PureAire’s oxygen monitor contains a zirconium sensor, which performs reliably for up to 10 years. This long-lasting sensor makes our oxygen monitors a good investment for many industries. These O2 monitors are easy to set up, work in a wide range of temperatures, and require no maintenance once they are installed. To learn more about oxygen deficiency monitors from PureAire, visit www.pureairemonitoring.com.

Source